At Virgilio Cena & Figli S.p.A., quality is not an end result but a principle that guides every stage of our work. From selecting certified materials to the careful control of each production process, we guarantee high and consistent standards over time. We operate with a management system compliant with ISO 9001 and rely on an in-house laboratory equipped for tests and inspections, supported by audits from qualified external bodies. In this way, every component leaving our plants carries not only precision and reliability, but also the certainty of having been made in full compliance with regulations and our customers’ expectations.

Quality is not a destination, but a journey.

Products selection

Each supply starts from certified and carefully selected materials, chosen to ensure high and long-lasting performance.

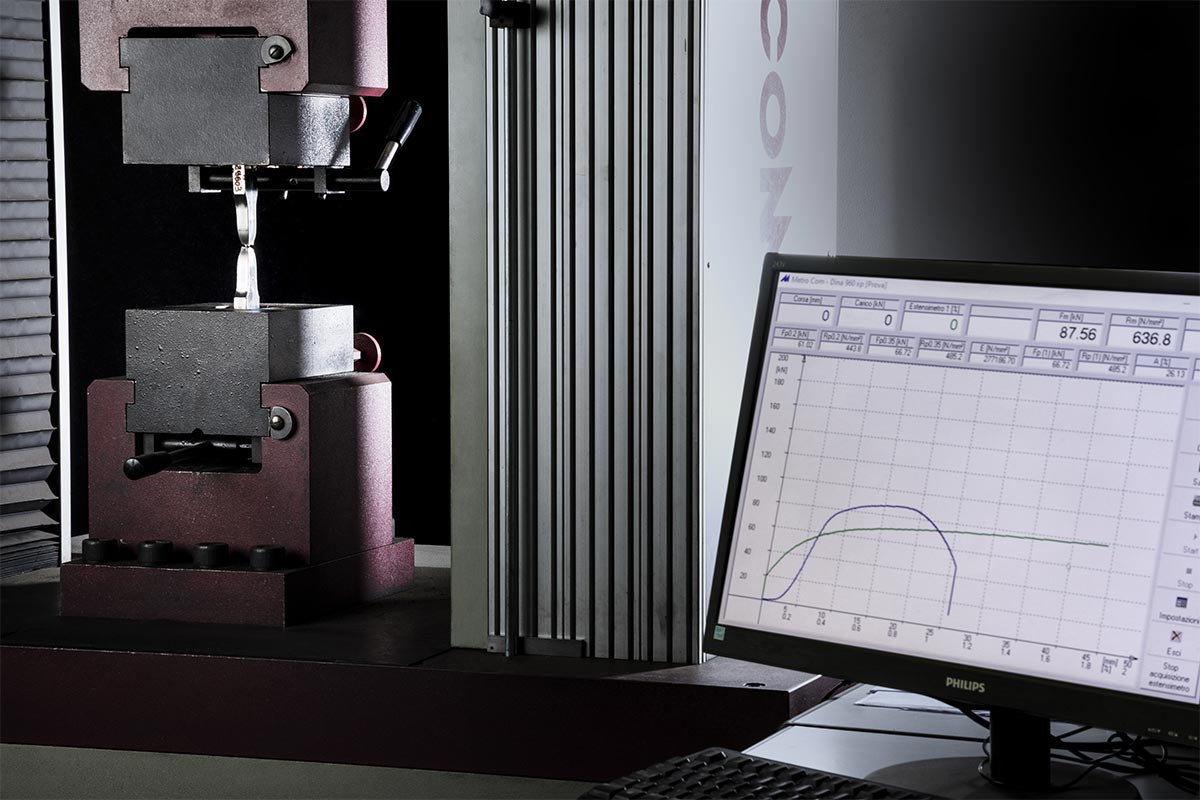

Controls and Inspections

Every production phase undergoes strict checks, with internal tests and verifications carried out by qualified external laboratories.

Our Certifications

We operate according to ISO 9001 certified management systems, ensuring safe, traceable processes that comply with international standards.

Precision, control, reliability

For us, quality is not just compliance with standards, but a daily commitment to exceeding expectations. Each component is designed and manufactured with attention to detail, thanks to a know-how built over decades of experience and continuously updated. Constant staff training and the adoption of advanced technologies allow us to guarantee reliable, safe, and repeatable results, strengthening our customers’ trust over time.

Certified quality, guaranteed trust

We operate under a management system compliant with ISO 9001, ensuring controlled and traceable processes at every stage.

Our certifications confirm a constant commitment to offering safe, reliable products that meet international standards.

Our certifications confirm a constant commitment to offering safe, reliable products that meet international standards.

-

UNI EN ISO 9001:2015Certified Quality Management System ensuring process control, consistency and full traceability across all operations.Download Other download

UNI EN ISO 9001:2015Certified Quality Management System ensuring process control, consistency and full traceability across all operations.Download Other download -

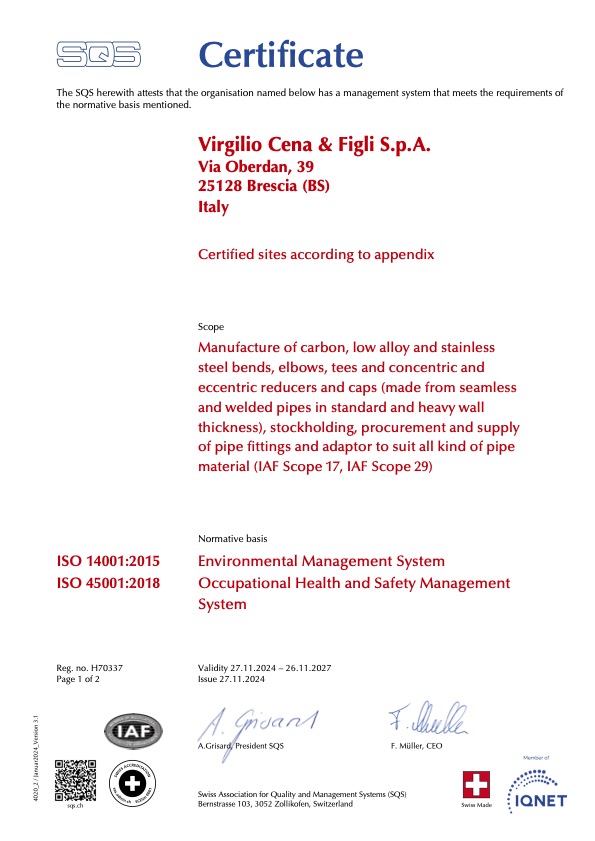

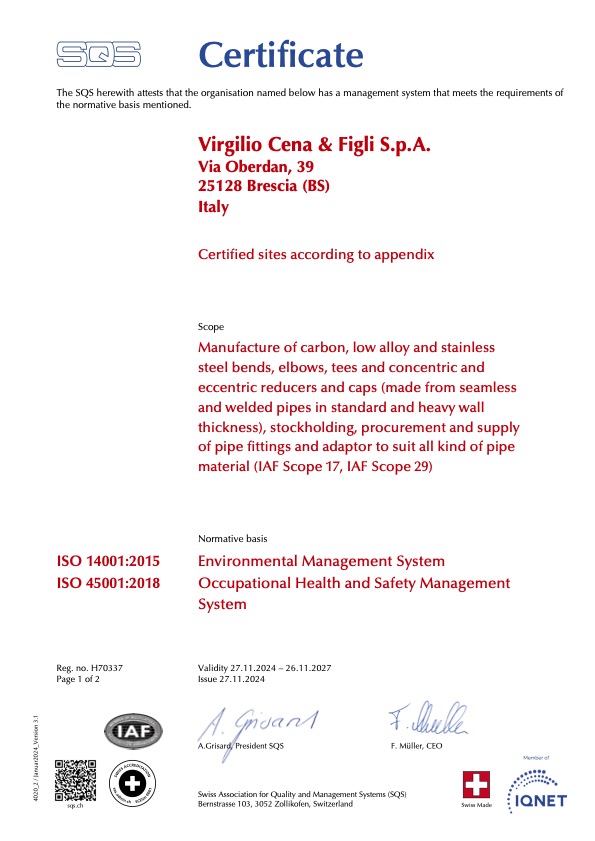

UNI EN ISO 14001:2015Certified Environmental Management System confirming a responsible approach to sustainability and compliance with global standards.Download

UNI EN ISO 14001:2015Certified Environmental Management System confirming a responsible approach to sustainability and compliance with global standards.Download -

UNI EN ISO 45001:2023Certification that reflects the company’s ongoing commitment to health, safety and risk prevention in the workplace.Download

UNI EN ISO 45001:2023Certification that reflects the company’s ongoing commitment to health, safety and risk prevention in the workplace.Download -

Pressure Equipment DirectiveProducts designed and manufactured in accordance with the European Directive 2014/68/EU, ensuring maximum safety and reliability.Download

Pressure Equipment DirectiveProducts designed and manufactured in accordance with the European Directive 2014/68/EU, ensuring maximum safety and reliability.Download -

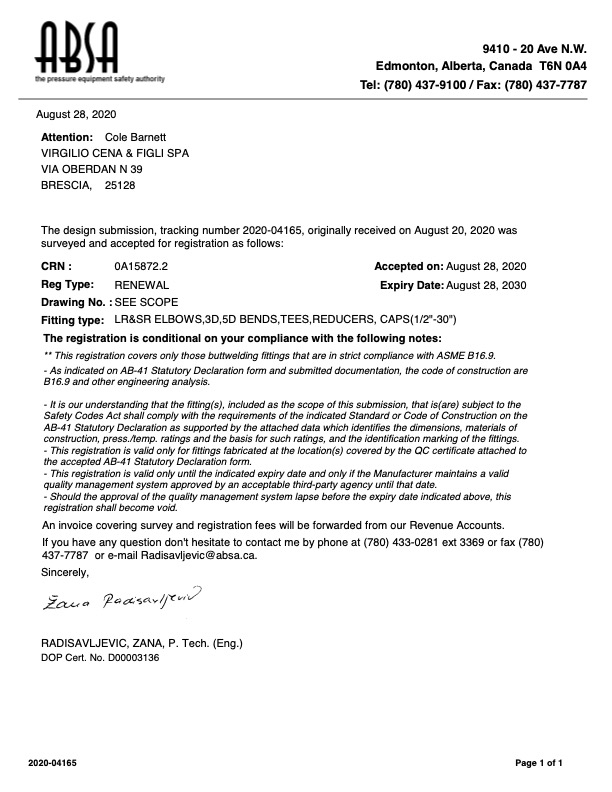

Canadian RegistrationConformity with Canadian standards for pressure equipment, enabling safe use and distribution across North America.Download

Canadian RegistrationConformity with Canadian standards for pressure equipment, enabling safe use and distribution across North America.Download -

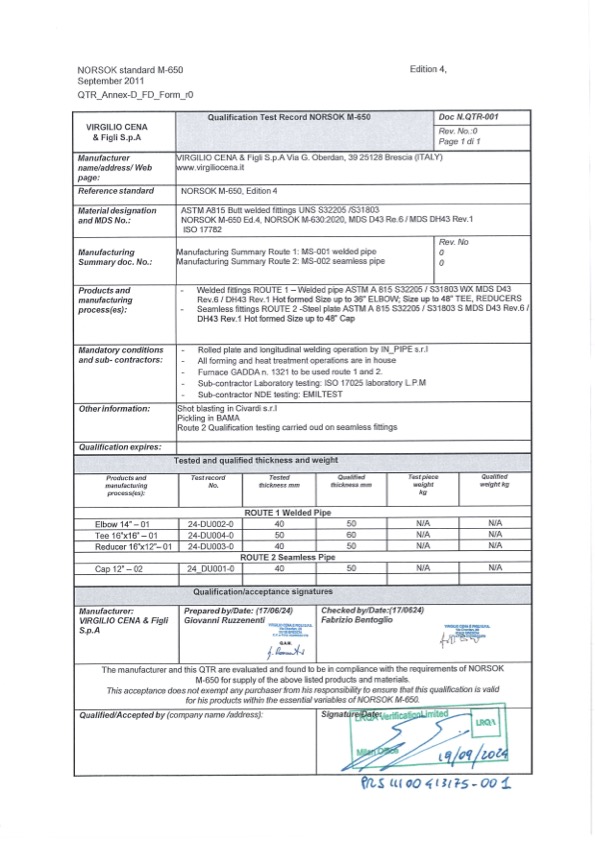

NORSOKCompliance with Norwegian offshore standards, meeting the highest technical and safety requirements for oil & gas applications.Download

NORSOKCompliance with Norwegian offshore standards, meeting the highest technical and safety requirements for oil & gas applications.Download

Liquid Penetrant Testing – LPT

Liquid Penetrant Testing is a non-destructive inspection method used to detect surface-breaking defects such as cracks, porosity, or laps on metallic components. A colored or fluorescent penetrant is applied to the part, allowed to seep into any discontinuities, and then removed from the surface. A developer is then applied to draw out the penetrant from flaws, making them visible under normal or UV light. This technique is ideal for ensuring the integrity of machined and welded fittings.

Magnetic Particle Testing – MT

Magnetic Particle Testing is a non-destructive method for detecting surface and near-surface defects in ferromagnetic materials. The component is magnetized, and fine magnetic particles are applied to the surface. Any discontinuity that interrupts the magnetic field causes the particles to gather, forming visible indications of cracks or other flaws. MT is widely used for quality control of forged and machined fittings to guarantee structural reliability.